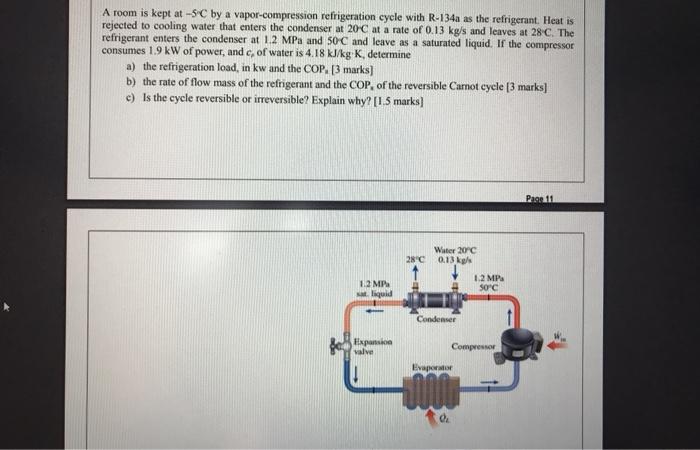

The heat removed from the refrigerant by the condenser is – In the realm of refrigeration, the condenser plays a pivotal role in the heat transfer process, removing heat from the refrigerant to maintain the system’s efficiency. This article delves into the mechanisms, design considerations, and performance evaluation of condensers, exploring their impact on refrigerant properties and refrigeration cycle performance.

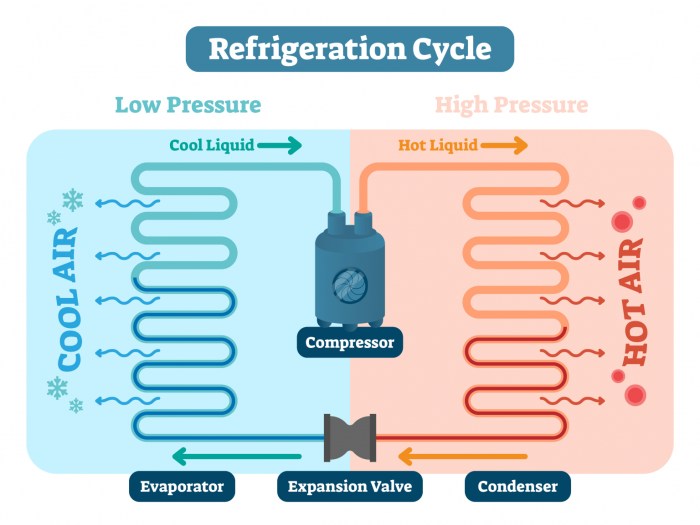

As the refrigerant circulates through the refrigeration system, it absorbs heat from the environment or cooled space. The condenser, acting as a heat exchanger, dissipates this absorbed heat into the surrounding environment, typically through air or water. This heat removal process is essential for maintaining the refrigerant’s cooling capacity and ensuring the system’s overall efficiency.

Condenser’s Role in Refrigeration Cycle: The Heat Removed From The Refrigerant By The Condenser Is

In a refrigeration system, the condenser plays a crucial role in removing heat from the refrigerant, enabling the system to cool the desired space. The heat removed by the condenser is essential for maintaining the refrigeration cycle and achieving efficient cooling performance.

The condenser is typically located in the outdoor unit of the refrigeration system. It consists of a series of tubes or coils through which the refrigerant flows. As the refrigerant passes through the condenser, it releases heat to the surrounding environment, typically through air or water.

This heat transfer process is critical for the proper functioning of the refrigeration system.

Heat Transfer Mechanisms in Condenser

The condenser primarily utilizes two heat transfer mechanisms: conduction and convection.

- Conduction: Heat is transferred from the refrigerant to the condenser tubes through direct contact. The refrigerant flows through the tubes, while the heat is conducted through the tube walls to the surrounding environment.

- Convection: Heat is transferred from the condenser tubes to the surrounding air or water through convection currents. As the refrigerant releases heat, it causes the surrounding air or water to rise, creating convection currents that carry the heat away from the condenser.

Heat exchangers play a vital role in enhancing the heat transfer process in the condenser. Heat exchangers are devices that facilitate the transfer of heat between two fluids. In the condenser, the heat exchanger is designed to maximize the surface area between the refrigerant and the surrounding environment, allowing for efficient heat removal.

Condenser Design and Optimization, The heat removed from the refrigerant by the condenser is

Condensers come in various designs, each suited for specific applications.

- Air-cooled condensers: These condensers use air as the cooling medium. They are commonly used in residential and commercial refrigeration systems due to their simplicity and cost-effectiveness.

- Water-cooled condensers: These condensers use water as the cooling medium. They are typically used in industrial refrigeration systems where higher cooling capacities are required.

The efficiency of a condenser is influenced by several factors, including the surface area of the heat exchanger, the temperature difference between the refrigerant and the surrounding environment, and the flow rate of the cooling medium.

Condenser optimization strategies focus on improving heat transfer efficiency by increasing the surface area, optimizing the flow rate, and maintaining a suitable temperature difference. This can be achieved through design modifications, such as using enhanced heat transfer surfaces or employing variable-speed fans to regulate airflow.

Impact on Refrigerant Properties

The heat removed by the condenser significantly affects the properties of the refrigerant.

- Pressure: As heat is removed from the refrigerant, its pressure decreases. This pressure drop is essential for the proper functioning of the refrigeration cycle.

- Temperature: The heat removal process also causes a decrease in the refrigerant’s temperature. This temperature reduction is crucial for achieving the desired cooling effect.

The relationship between heat removal, refrigerant pressure, and temperature is governed by the refrigerant’s thermodynamic properties. Understanding these relationships is essential for optimizing condenser performance and ensuring efficient system operation.

Condenser Performance Evaluation

Evaluating condenser performance is crucial for ensuring optimal system efficiency.

- Capacity: The capacity of a condenser is measured in terms of the amount of heat it can remove from the refrigerant per unit time. It is typically expressed in British Thermal Units per hour (BTUH).

- Efficiency: Condenser efficiency refers to its ability to remove heat while consuming minimal energy. It is often measured using the Coefficient of Performance (COP), which is the ratio of cooling capacity to power consumption.

Factors affecting condenser performance include fouling, airflow, and refrigerant charge. Fouling refers to the accumulation of dirt or debris on the condenser coils, which can impede heat transfer. Airflow is critical for removing heat from the condenser, and any obstructions or restrictions can reduce performance.

Proper refrigerant charge is also essential, as insufficient or excessive refrigerant can negatively impact condenser efficiency.

Condenser Applications and Case Studies

Condensers are widely used in various refrigeration systems, including:

- Air conditioners: Condensers are used in air conditioners to remove heat from the refrigerant and release it to the outside environment, providing cooling for indoor spaces.

- Refrigerators and freezers: Condensers are essential components of refrigerators and freezers, enabling the removal of heat from the food and maintaining the desired cooling temperatures.

- Industrial refrigeration: Condensers are used in industrial refrigeration systems for cooling processes in various industries, such as food processing, manufacturing, and healthcare.

Case studies and real-world examples demonstrate the impact of condenser performance on system efficiency. For instance, in a study conducted by the Air-Conditioning, Heating, and Refrigeration Institute (AHRI), it was found that a 10% increase in condenser efficiency can lead to a significant reduction in energy consumption and operating costs.

Detailed FAQs

What is the primary function of a condenser in a refrigeration system?

The primary function of a condenser in a refrigeration system is to remove heat from the refrigerant, dissipating it into the surrounding environment.

How does the condenser affect the properties of the refrigerant?

By removing heat from the refrigerant, the condenser causes a decrease in its temperature and pressure, affecting its thermodynamic properties and cooling capacity.

What are the different types of condenser designs used in refrigeration systems?

Common condenser designs include air-cooled condensers, which use ambient air for heat dissipation, and water-cooled condensers, which utilize water as the cooling medium.